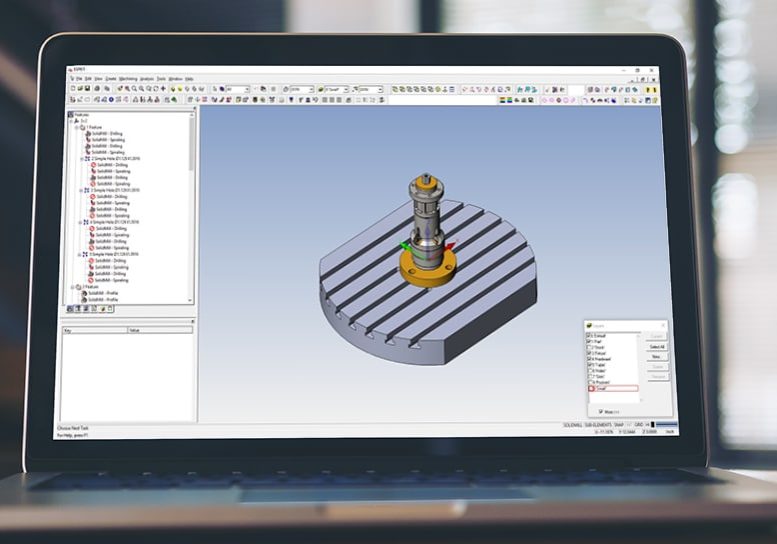

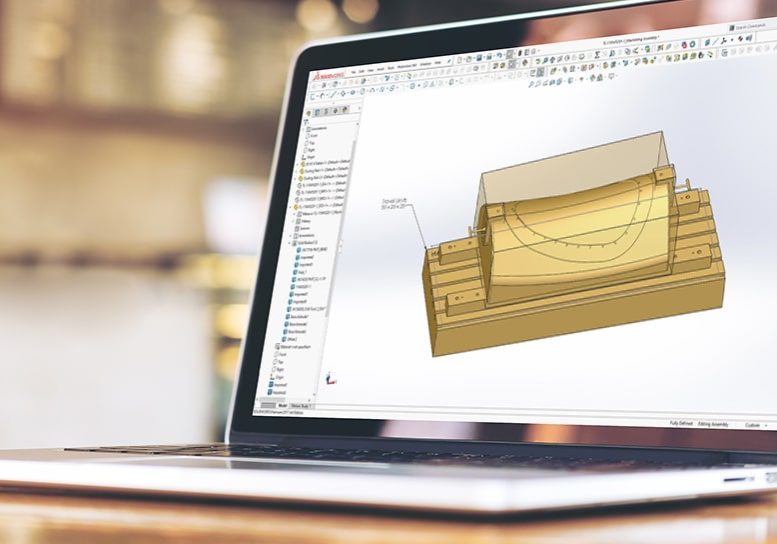

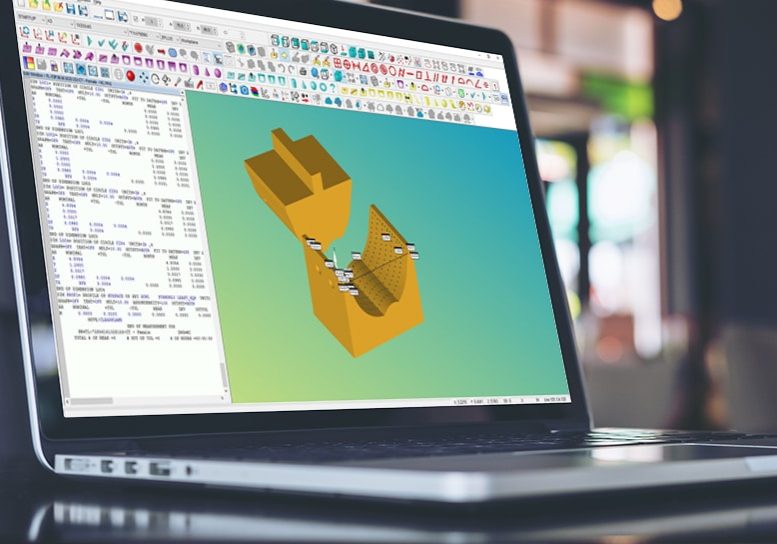

Cutting Edge Technologies understands the difficulty to expertly staff a programming department in a machine shop. It is difficult to find qualified CNC or CMM programmers to keep up with shop demands. Finding the right workforce balance as new contracts come in puts your business at risk. Cutting Edge can work with you to increase your programming capacity and/or tackle short-term surges as needed.

We have a wealth of experience programming and performing to ISO, AS9100, and other industry standards. Our parts and programming have helped various organizations in aerospace, automotive, commercial, general aviation, industrial, and other manufacturing uses. We’re familiar with machining aluminum, stainless steel, copper, wood, plastics, and more. From programming to modeling to complete turnkey solutions, Cutting Edge is capable of providing premium, precise results.